Catalog

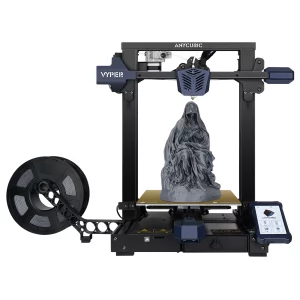

3D Printers

Anycubic Kobra

Anycubic Kobra Plus

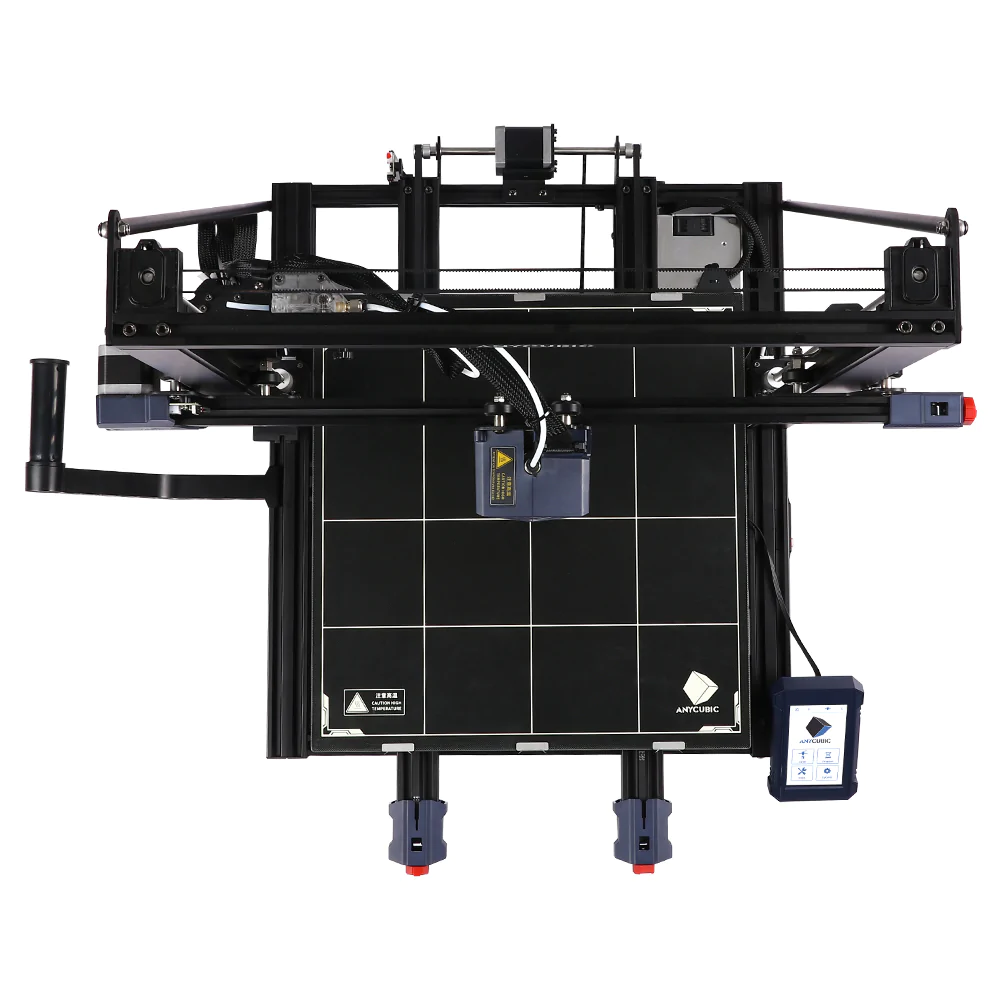

Anycubic Kobra Max

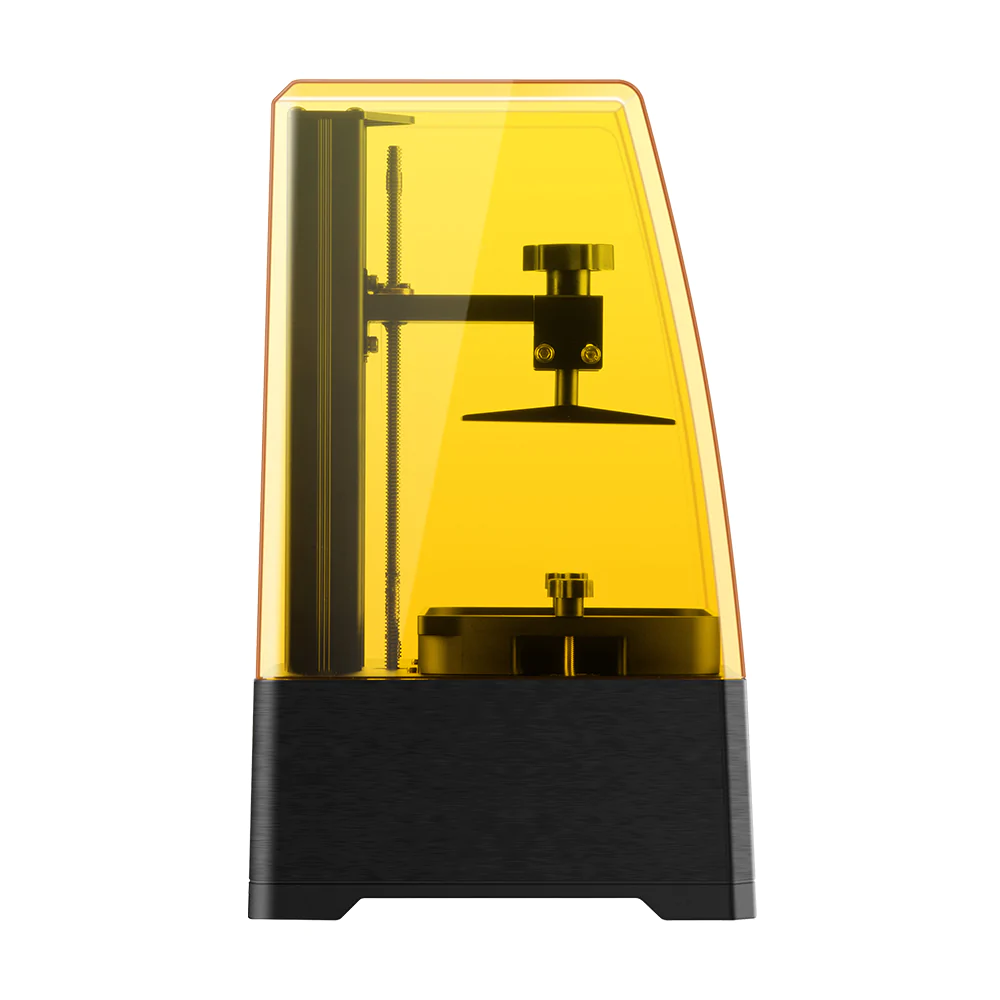

Anycubic Photon M3

Anycubic Photon M3

916,00 ₼Anycubic Kobra

916,00 ₼Anycubic Kobra Plus

1.629,00 ₼Anycubic Kobra Max

1.833,00 ₼These are different plastics for different tasks. And you can not say that one is better than the other. For each specific task, you just need to choose the right plastic, taking into account the requirements.

ABS

PROS: It has better flexibility, heat resistance and is easy to process.

CONS: has shrinkage, less interlayer adhesion (may crack). May emit an unpleasant odor when printed. Shrinkage makes it difficult to print large parts.

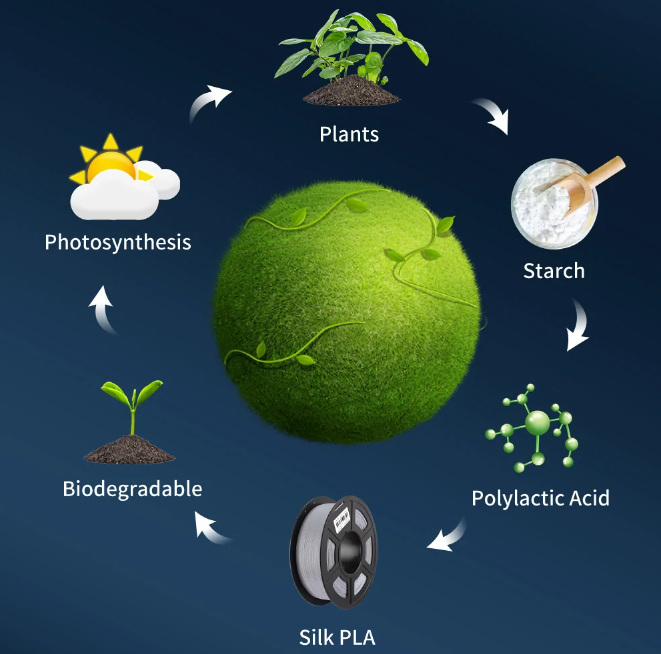

PLA

PROS: It has great strength, hardness. Virtually no shrinkage, easy to print. Eco-friendly, does not emit unpleasant odors when printing.

CONS: low heat resistance. Difficult to process due to hardness.

How to paint printed products?

Acrylic paints can be used for painting finished products. They can be purchased in the form of cylinders in construction and auto stores. And in the form of paint sets for drawing in art salons.

Nitro paints can not be used - they damage the plastic.

Alkyd paints cannot be used either - they do not stick to the surface of plastic parts.

There are two plastic standards used in 3D printers today, these are 1.75 mm and 2.85 (3.00) mm.

Is there a difference, and what to choose?

There is no difference when printing.

If the printer is equipped with a Bowden extruder (this is when the feed motor is located on the printer body), then the use of 2.85 (3.00) mm plastic allows the use (with the necessary settings) of rubber-like types of plastic.

For 3D printers equipped with a Direct extruder (the vast majority of them), there is no difference between the plastics used.

95% of all 3D printers are built for use with 1.75mm filament. Therefore, new types of materials are produced primarily with a diameter of 1.75 mm. Filament, 2.85 mm in diameter, is produced, usually after a while.

That's all the features.

It all depends on what filling to print the model with. If you print a large (about 20 cm) part with 100% infill, you can use up a whole coil. But mostly non-monolithic parts are printed.

For decorative details, the percentage of filling is 10-25%.

For functional 30-50%.

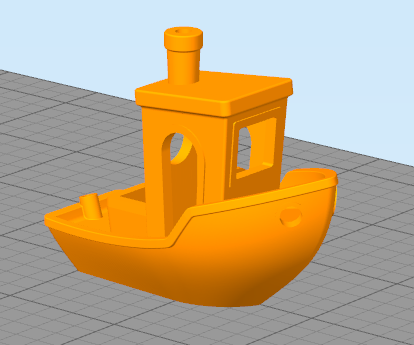

Here, the well-known boat, 60 mm long.

The weight of the printed model, when filled with 20% - 12.5g. That is, from one kilogram of plastic, you can print 80 such boats.

Materials

Anycubic 1.75mm PLA Filament

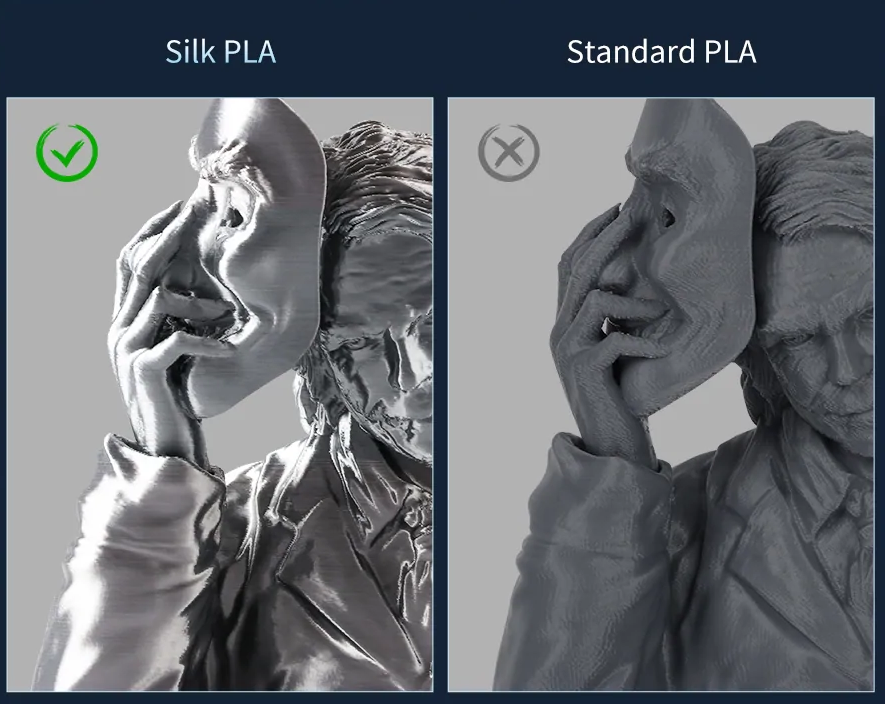

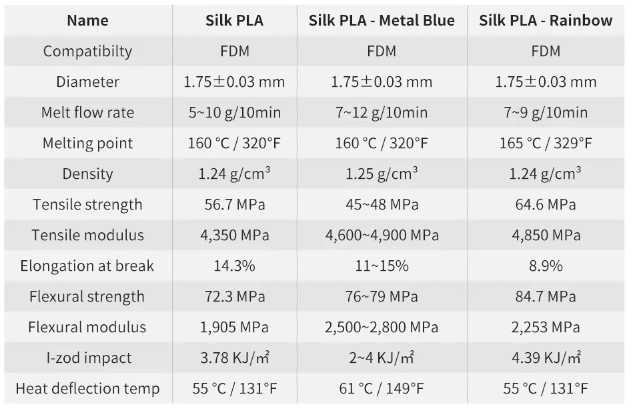

Anycubic 1.75mm Silk PLA 3D Printer Filament 1KG

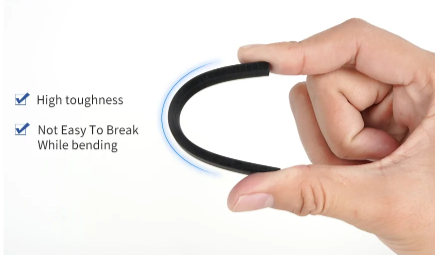

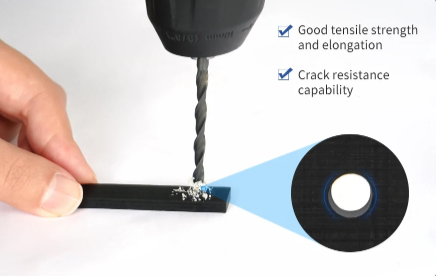

Anycubic Flexible Tough Resin

Anycubic DLP Craftsman Resin Package

3D Scanners